Workshop

Of course, you take great care of your Heinkel scooter, and feel that nothing but the best care is good enough for your vehicle.

The best care is what we offer in Eindhoven, at HEINKEL SERVICE NEDERLAND.

Here, you’ll find the best equipped Heinkel workshop of the Netherlands and surroundings.

H S N Workshop

Meanwhile, I have accumulated over 50 years of experience in working on the Heinkel scooter, and have travelled over 500 thousand kilometer on various scooters. You can imagine that I have been through just about anything during these years.

Whether it involves a simple oil change, a complete refurbishment or restoration, I am at your service to bring and keep your scooter in mint condition.

It is also possible to have me pick up your scooter and bring it back to you after the completion of repairs.

To this end, we have a beautiful service bus at your service. ( See chapter service )

Workshop equipment.

Of course, the workshop is well equipped, allowing us to give your Heinkel scooter the best care possible. The selection of tools in our workshop includes the following:

Work table. 2 pieces.

To be able to work properly, the scooter has to be raised to the right level.

It goes without saying that, when testing the engine, we use exhaust extraction.

|

|

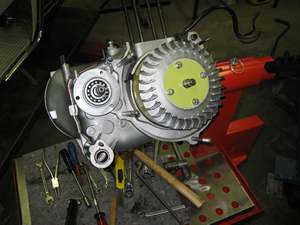

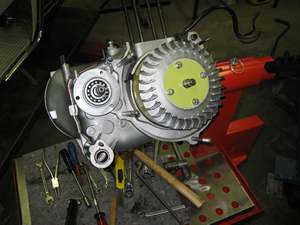

Engine work block.

Engine block can be rotated in all directions to facilitate the work.

|

|

Degreasing system.

After disassembly, all parts have to be made free of grease.

You can’t perform work on a dirty engine. |

|

Blasting cabin.

Often, the aluminum is quite weather beaten.

After glass bead blasting, it is as beautiful as if it comes straight from the factory.

Even small coated parts can be blasted and recoated.

Of course, large objects that need to be coated are sent to the paint workshop. |

|

Oven.

To be able to shrink bearers in the engine block, the carter halves are first heated to 150 degrees for a period of 30 minutes. |

|

Valve grinding machine.

Often it is possible to refurbish the existing valves by grinding them.

This will save you a lot of money. |

|

Taping Tools.

Once the valves have been ground, the valve seats have to be refurbished as well.

This taping tool is very strong, thanks to the diamond coating, guaranteeing a 100% fit. |

|

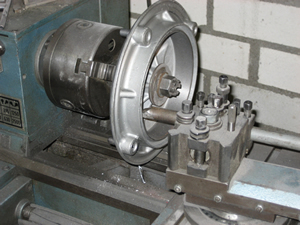

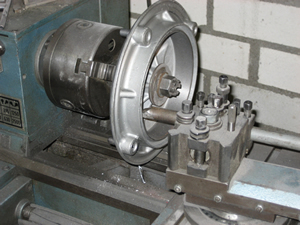

Lathe.

If the brake drum is damaged, it has to be dialed out. This is something I can do in my own workshop as well.

And if you opt for using the brake pads with the new friction material of H.S.N, the brakes will even work better than they originally did !!

|

|

Pillar drill.

Sometimes, a threaded hole has to be repaired, such as the oil drain plus.

The new threaded hole has to be applied perpendicularly of course.

And the detent has to be drilled perfectly straight as well for proper operation.

Also see chapter Service |

|

Tire assembly machine.

To disassemble and then reassemble the tires the proper way, a tire machine is indispensible.

The machine has been adjusted to our small and narrow wheels of course.

No hassle with tire levers

No more damaged wheels.

No more injured fingers. |

|

Engine hoist.

To list the engine from the frame and to refit it after repair or revision an electric battery hoist is a valued tool. |

|